Where is the iPhone Made and Assembled?

Most people know that the iPhone is being made in China and designed in California. Apple even mentioned this information on its iPhone a while back. But is this true? Are all the components of the iPhone made in China? In this article, we will discuss where the iPhone is being made and Assembled.

A short answer to where the iPhone is being made and Assembled would be as follows.

Apple has its iPhones made in China, and to be more specific, in Shenzhen. However, most iPhone parts, such as the display, chipsets, and memory cards, are brought from other countries, such as Japan, Korea, Taiwan, Singapore, and even Europe.

I bet that this is not something you’ve expected to read. At best, most people think that the iPhone is in its entirety manufactured in China. And that’s why I will breakdown in this article where the iPhone is made and why Apple has chosen to manufacture its iPhones overseas.

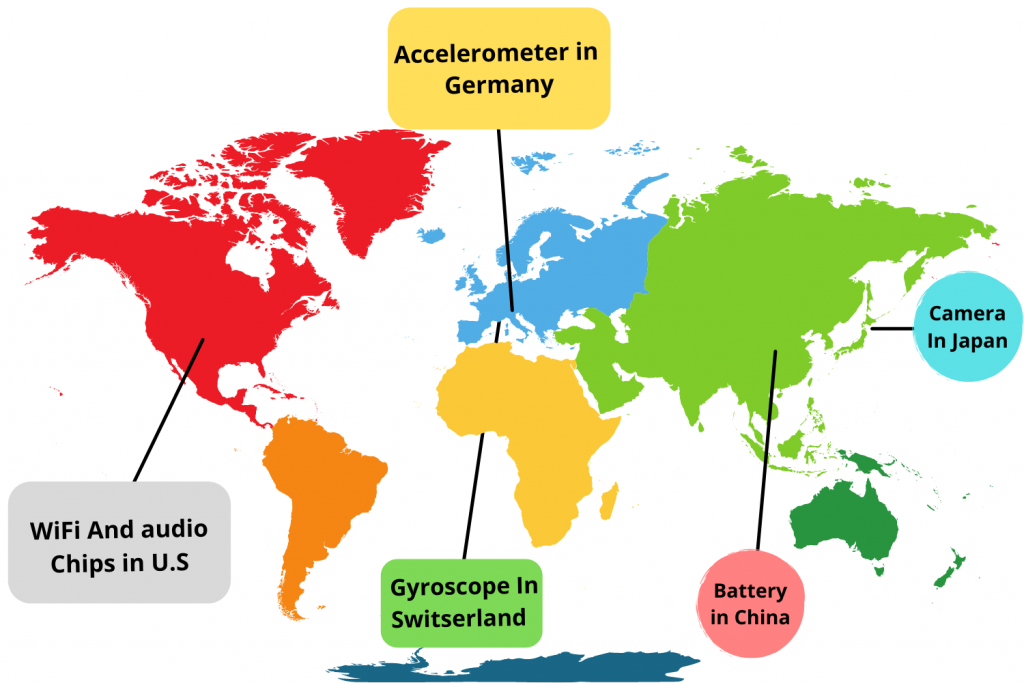

The places where the iPhone is Made

Besides having a dedicated design team in California, Apple has chosen to keep manufacturing the iPhone in Shenzhen at Foxconn Technology Group.

In case you didn’t know, Foxconn is a multinational electronic contract manufacturer located in Tucheng, New Taipei City, Taiwan, South Korea, and other places. But as stated a minute ago, the iPhone is not 100% Assembled in China. Some parts need to be created elsewhere to give the iPhone all its components to function well.

As a matter of fact, there isn’t just one company responsible for creating all the parts of the iPhone. There are dozens of other companies accountable for assembling these components. Therefore, it isn’t simple to mention every company involved in this iPhone creation project.

So I’ve made a table to give you an overview of the manufacturers and where their headquarters are located.

An overview of where the components of the iPhone are coming from.

As stated, there are way too much manufacturers to list them in an alinea. In fact, it would be one unclear mess. Especially when I need to mention all the components along with their manufacturers and the locations where these manufacturers are based.

So I’ve made a table where you can find most components of the iPhone together with their manufacturers and location.

| Component | Company | Location |

|---|---|---|

| Camera | Sony / Qualcomm | Japan / U.S. |

| Battery | Samsung / Sunwoda | South Korea / China |

| Wi-Fi | Murat | U.S. |

| Touch ID | Xintex / TSMC | Taiwan |

| A-series Processor | Samsung / TSMC | South Korea / Taiwan |

| Accelerometer | Bosh | Germany |

| Compass | AKM Semiconductor | Japan |

| Chips For Cellular Networking | Qualcomm | U.S. |

| Glass Screen | Corning | U.S |

| Flash Memory | Toshiba | Japan |

| LCD Screen | Sharp / LG | Japan / South Korea |

| Touch-Screen | Broadcom | U.S. |

| Gyroscope | STMicroelectronics | Switserland |

So basically, the iPhone is not made in America?

The answer is partly. As for its software, Apple has chosen to trust this part to companies located in America. But the code that iOS is made from is not the only made-in-America ingredient.

The glass, for example, is manufactured in Kentucky. Cirrus Logix, located in Texas, manufactures the chip where the audio is coming from.

Even the controller chips, a part located on the inside of the iPhone, are made by PMC and Broadcom Corp., both based in California.

Why Does Apple Assemble iPhone Components Elsewhere?

You may think by now, but why all this trouble? Why has Apple chosen to walk this challenging route? Is it not easy and efficient to just make all these components at Apple’s headquarters?

Indeed, Apple has the resources to build an iPhone from start to finish without outsourcing any of it, but doing it this way is more efficient than you may think.

Inadequate amount of human resources

The reason why it’s quite impossible to manufacture every single component of the iPhone in America because there isn’t enough manpower to support the whole production process.

To put that in perspective, only the factory in China that’s responsible for manufacturing some of the parts of the iPhone has around 200,000 employees.

If this is true for some parts of the iPhone, what about all the other features we’ve just talked about? How many workers would Apple need to accommodate to be able to manufacture the iPhone? The number of employees will then go in the millions.

And we’re just talking about the iPhone. We haven’t looked at the other Apple products. So as you can imagine, it would be highly inefficient if Apple manufactured every single component of every product they design themselves.

“it would be highly inefficient if Apple manufactured every single component of every product they design themselves.”

Shelter For Employees

And speaking of accommodations of employees, in China, they go even one step further. A quarter of the workforce of big tech companies lives in company-owned dormitories, which means that many employees are working and living in or around the factory!

And you may think, good luck with finding people who are willing to live and work at the factory. Well, that’s the last thing big Chinese companies worry about.

They can hire the right amount of people in a couple of days since these kinds of jobs are in high demand in China.

The costs are lower

You may have guessed it, but manufacturing technology locally costs more. Not only because of the high loans you need to pay your American employees but also the benefits, insurances, and taxes that come with this package.

Quantity

And last but not least, it’s all about the number of iPhone components a manufacturer can build in the shortest amount of time. Especially before the release of new iPhone models.

Where Do iPhone Raw Materials Come From?

Now you know where most iPhone’s components are being assembled, you may be asking yourself the following:

But what about the Raw Materials of the iPhone? Where do these come from?

Like most iPhone components, raw materials are extracted from all over the world. Take gold, for example. This material is brought from Peru. Other minerals, like copper, are extracted from Chile.

Where is The Processor of The iPhone Manufactured?

With the transition to Apple silicon, the Processor of the iPhone is manufactured by Apple Inc. But they are still partnered up with TSMC, which is responsible for creating iPhone’s fastest processors. This information may change in the future, but we know that iPhone’s Processor is still manufactured by TSMC, a company that’s not based in the US but in Taiwan.

The Difference between Assembled and Made

By now you’ve read a couple of times the words “Assembled” and “Made” and I need to tell you that there is a difference between both words.

As you already know, the meaning of the word “making” is creating the actual component that eventually will be part of the iPhone somewhere in the creation procedure.

Assembling means collecting all those components, created whether in America or somewhere else in the world, and merge them into a well-working iPhone.

Apple has chosen to walk this route because it wanted to leave some components’ manufacturing process to the specialists. Yes, they could fabricate a working iPhone from start to finish independently, but that would be an inefficient and time-consuming process.

Instead, they outsource certain parts to specialists who know precisely how to create a perfect working component as efficiently and qualitatively as possible.